PRECISION MACHINING CAPABILITIES

PMP offers a wide range of forging equipment and precision processes including high-velocity presses to meet unique specifications and requirements. Our production capabilities range from prototyping to mass production.

CORE CAPABILITIES

- Near net precision forging with tolerances up to ±0.005 inches

- Net and near-net forgings and machining up to 110 lbs. and 250 sq. inches in plain view area

- Multi-alloy forging

- Titanium

- Stainless Steel

- Nickel Alloys

- Maraging Steel Alloys

- Cobalt Chrome

- Customer Specified Alloys

KEY EQUIPMENT

PMP 8,800 Ton Screw Press (video link)

- Near-net forgings up to 100 lbs. with 100-120 square inches of surface area

- Maximum Tonnage (Continuous Forging): 8,800 US Tons

- Maximum Die area: 20 in x 40 in

- Target Part Sizes ~16”+ diameter with flash

- Advantages

- Wide range of parts

- High repeat accuracy

- High reliability and flexibility

- Maximum efficiency

Other Presses

- 8 Screw Presses ranging from 200 to 11,000 tons

- 7 High Velocity Presses ranging from 125,000 to 300,000 maximum foot-pounds

- 9 Mechanical Presses ranging from 75 to 1,500 tons

- 2 Hydraulic Presses ranging from 300 and 800 tons

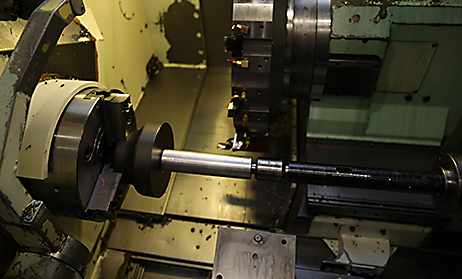

Lathe & Milling Machines

- 14 CNC lathes

- 15 CNC mills with up to 5 axis

IN-HOUSE SERVICES

- Pre-and-post forging operations (per customer request) for added assurance and specification refinement

- Tooling manufacturing

- Heat Treating for titanium components

- Shot blast and sand blast

- Vibro-deburr polishing and hand polishing

- Chemical Milling for titanium alloys

- Chemical processing

- Hot Caustic Salt Bath Cleaning for titanium alloys

TESTING

- Fully equipped Metallurgical Laboratory to cut and machine testing samples

- Mechanical property analysis

- Chemical property analysis

- Microstructural evaluation

- Other relevant verifications

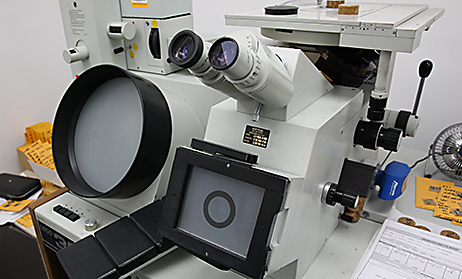

- CMM & 3D Scanning Capabilities

- Coordinate measuring machine (CMM) inspection

- 3D laser scanning inspection

- Optical comparator inspection

- Nondestructive Testing

- Florescent penetrant inspection

- Magnetic particle inspections

- Calibration Lab

- Covers more than 90% of instrument/measuring equipment calibrations needed