FULL-SERVICE SUPPLIER

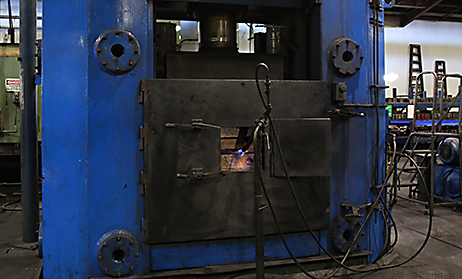

PMP provides its customers with a complete in-house array of services, including engineering, metallurgical assistance, quality/tolerance testing, product prototype development, tooling fabrication, heat treatment, milling and pre- and -post forging operations.

- Custom manufacturing process according to technical specifications, schedules and cost efficiency

- Engineering consultation to optimize cost containment and requirements

- Onsite customer support and extensive application experience

- Fast turn-around from initial product development to full scale production

- Machining, milling and turning using the latest CNC equipment, EDM (Electrical Discharge Machining) and supporting operations as requested.

- Sister company True Position Technologies (TPT) offers more complex machining and part finishing capabilities to provide parts direct to assembly line replenishment

QUALITY

PMP maintains the highest level of quality manufacturing with certified and compliant quality systems from numerous industry associations and manufacturing standards. PMP maintains quality system approvals with OEM prime contractors. PMP engineers work closely with quality control and production to ensure high safety and precision standards.

CERTIFICATIONS

- ISO 9001:2015 certified by Perry Johnson Registrars, Inc

- ISO 13485:2016 for Quality Management System for Medical Devices certified by Perry Johnson Registrars, Inc

- NADCAP for NonDestrutive Testing administered by Performance Review Institute (PRI)

- PMP complies with ITAR (International Traffic in Arms Regulations) Procedures and Policies